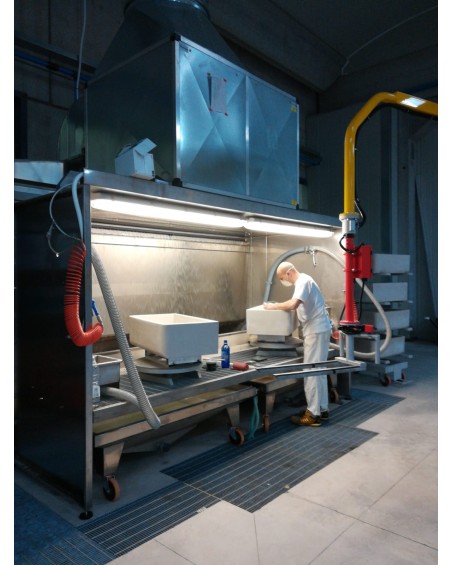

The finishing and testing booth is used for Ceramic Sanitary Ware Inspection

The finishing and testing cabin is made of stainless steel sheet at bent in order to give the machinery the necessary geometric characteristics and strength. The whole is robustly connected by means of welds with filler materials suitable for the materials to be connected. There are filter units with water curtain cascade, the inner part consists of labyrinth sheets and there is a barrel with a sprayer for dust abatement. Inside the hood there are stainless steel filters and automatic washing .

The extraction surface, that is the working area of the cabin is placed on the front and is equipped with a working lathe manually moved by the operator by means of a crank.

During the finishing phase, the air is filled with residual ceramic dust and is sucked in from the rear through a system of waterfalls and water veils, then flows through a series of plastic labyrinth droplet separators and is sucked by the fan to be then pushed outside through the exhaust chimney.

There are two removable lathes , two trays for dust collection and grid on the ground.

The machine is complete with electrical panel.

At the request of the customer it can be realized at one or two stations